Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibers, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material.

The panels vary in size but can range upwards of 64 by 8 feet (19.5 by 2.4 m) and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to 16 inches or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance.

Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. The products can be used for joists and beams that replace steel in many building projects. The term mass timber describes a group of building materials that can replace concrete assemblies. Broad-base adoption of mass timber and their substitution for steel and concrete in new mid-rise construction projects over the next few decades has the potential of turning timber buildings into a global carbon sink, which could help mitigate climate change.

Typically, engineered wood products are made from the same hardwoods and softwoods used to manufacture lumber. Sawmill scraps and other wood waste can be used for engineered wood composed of wood particles or fibers, but whole logs are usually used for veneers, such as plywood, medium-density fiberboard (MDF) or particle board. Some engineered wood products, like oriented strand board (OSB), can use trees from the poplar family, a common but non-structural species.

Alternatively, it is also possible to manufacture similar engineered bamboo from bamboo; and similar engineered cellulosic products from other lignin-containing materials such as rye straw, wheat straw, rice straw, hemp stalks, kenaf stalks, or sugar cane residue, in which case they contain no actual wood but rather vegetable fibers.

Flat-pack furniture is typically made out of man-made wood due to its low manufacturing costs and its low weight.

Engineered wood, also called mass timber, composite wood, man-made wood, or manufactured board, includes a range of derivative wood products which are manufactured by binding or fixing the strands, particles, fibers, or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite material.

The panels vary in size but can range upwards of 64 by 8 feet (19.5 by 2.4 m) and in the case of cross-laminated timber (CLT) can be of any thickness from a few inches to 16 inches or more. These products are engineered to precise design specifications, which are tested to meet national or international standards and provide uniformity and predictability in their structural performance.

Engineered wood products are used in a variety of applications, from home construction to commercial buildings to industrial products. The products can be used for joists and beams that replace steel in many building projects. The term mass timber describes a group of building materials that can replace concrete assemblies. Broad-base adoption of mass timber and their substitution for steel and concrete in new mid-rise construction projects over the next few decades has the potential of turning timber buildings into a global carbon sink, which could help mitigate climate change.

Typically, engineered wood products are made from the same hardwoods and softwoods used to manufacture lumber. Sawmill scraps and other wood waste can be used for engineered wood composed of wood particles or fibers, but whole logs are usually used for veneers, such as plywood, medium-density fiberboard (MDF) or particle board. Some engineered wood products, like oriented strand board (OSB), can use trees from the poplar family, a common but non-structural species.

Alternatively, it is also possible to manufacture similar engineered bamboo from bamboo; and similar engineered cellulosic products from other lignin-containing materials such as rye straw, wheat straw, rice straw, hemp stalks, kenaf stalks, or sugar cane residue, in which case they contain no actual wood but rather vegetable fibers.

Flat-pack furniture is typically made out of man-made wood due to its low manufacturing costs and its low weight.

-

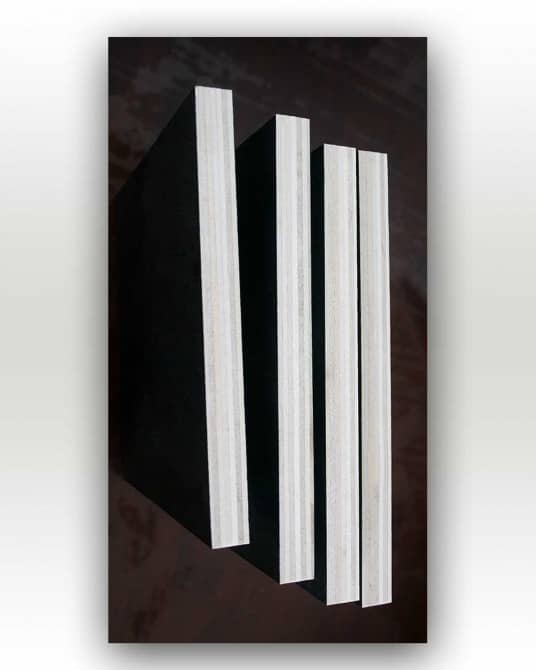

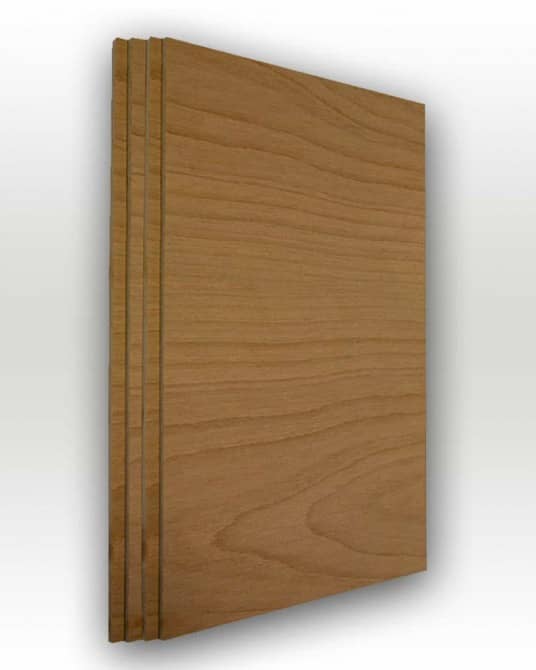

Veneer Door Skin Veneer Door Skin

$4.80Veneer laminated door skin panels are a type of manufactured hot press molded HDF panels, used high grade HDF panel with thin sheets of natural veneer made from log, using for making doors.

7 Commentaire(s) -

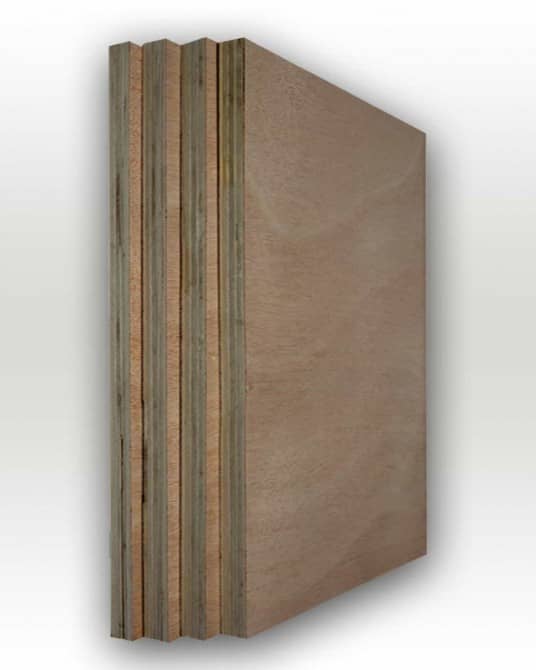

Plywood Plywood

$15.99Typical plywood panel has face veneers of a higher grade than the core veneers. The principal function of the core layers is to increase the separation between the outer layers where the bending stresses are highest, thus increasing the panel's resistance to bending. As a result, thicker panels can span greater distances under the same loads.

1 Commentaire(s) -

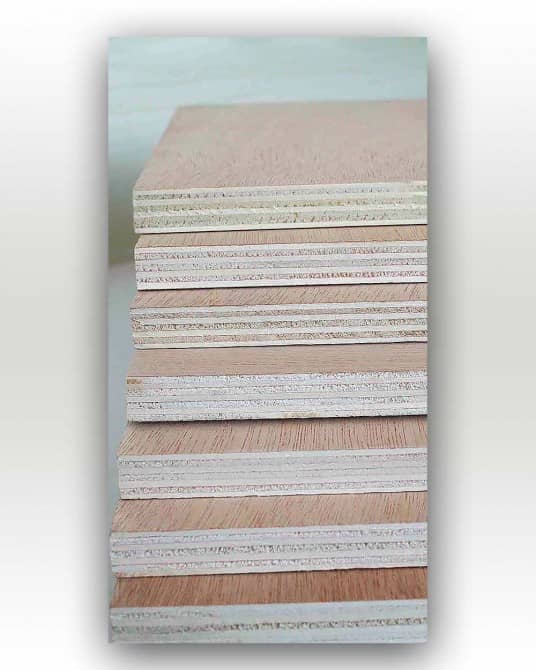

Laminated Plywood Laminated Plywood

$10.00Laminated plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another then coated with soft or hard thin sheet of PVC with smooth or 3D touchable wood grains sense in one or both sides.

1 Commentaire(s) -

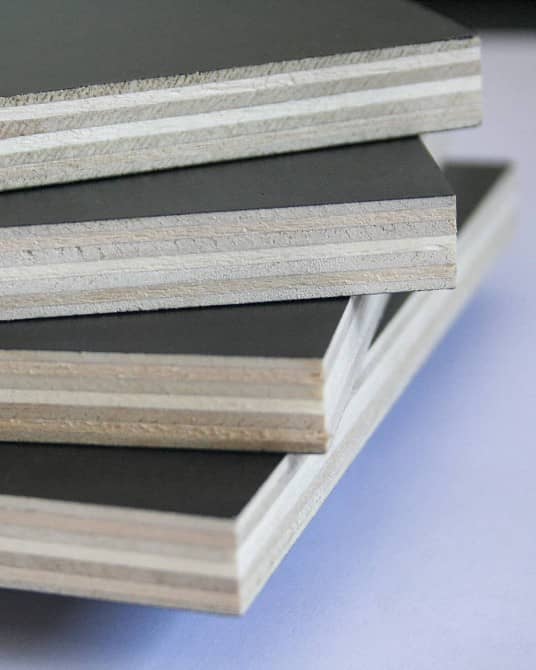

Plywood Plywood

$21.99Typical plywood panel has face veneers of a higher grade than the core veneers. The principal function of the core layers is to increase the separation between the outer layers where the bending stresses are highest, thus increasing the panel's resistance to bending. As a result, thicker panels can span greater distances under the same loads.

1 Commentaire(s) -

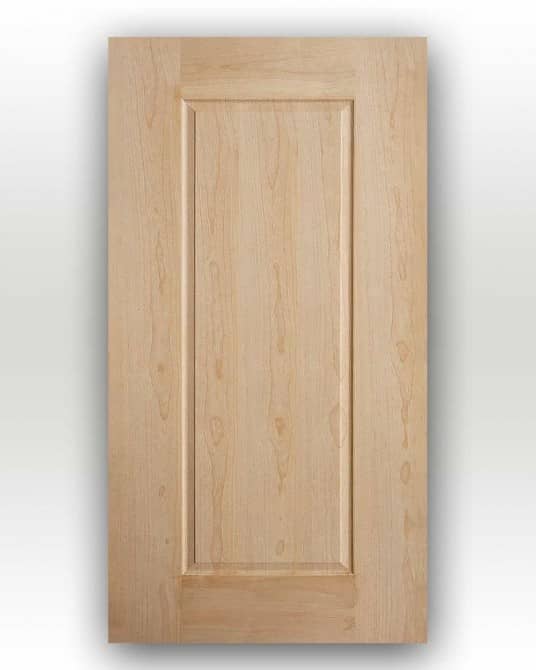

Wood Grain Melamine Door Skin Wood Grain Melamine Door Skin

$5.45Wood grain laminated door skin panels is a type of manufactured hot press molded HDF panels, used high grade HDF panel with thin sheets of substrates (water proof) melamine paper, using for making doors.

5 Commentaire(s) -

Laminated MDF Laminated MDF

$33.99Laminated MDF provides many of the advantages of MDF with a decorative PVC surface layer. In modern construction, spurred by the high costs of hardwoods, manufacturers have been adopting this approach to achieve a high-quality finishing wrap covering over a standard MDF board.

1 Commentaire(s) -

Veneer Door Skin Veneer Door Skin

$4.80Veneer laminated door skin panels are a type of manufactured hot press molded HDF panels, used high grade HDF panel with thin sheets of natural veneer made from log, using for making doors.

9 Commentaire(s) -

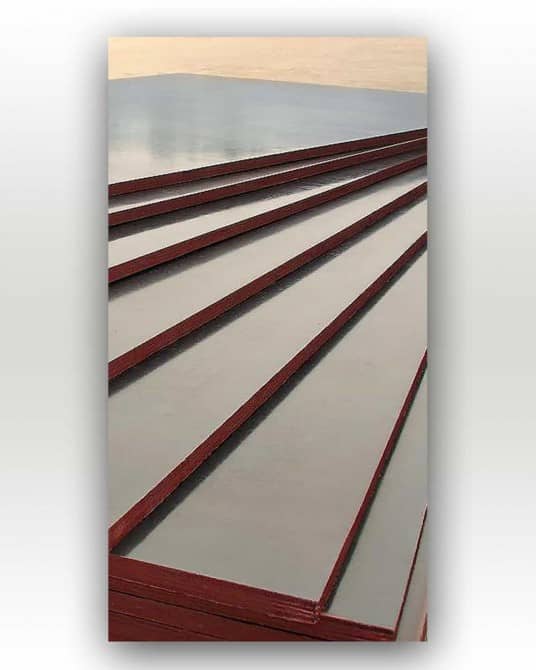

Construction Plywood Construction Plywood

$125.00Construction plywood is manufactured from durable face and core veneers, with few defects so it performs longer in both humid and wet conditions and resists delaminating and fungal attack. Its construction is such that it can be used in environments where it is exposed to moisture for long periods.

1 Commentaire(s) -

Raw MDF Raw MDF

$17.00Medium-density fiberboard (MDF) is an engineered wood panel made by breaking down hardwood or softwood residuals into wood fibers, MDF does not contain knots or rings, making it more uniform than natural woods during cutting and working.

1 Commentaire(s) -

Construction Plywood Construction Plywood

$12.00Construction plywood is manufactured from durable face and core veneers, with few defects so it performs longer in both humid and wet conditions and resists delaminating and fungal attack. Its construction is such that it can be used in environments where it is exposed to moisture for long periods.

1 Commentaire(s) -

Melamine Door Skin Melamine Door Skin

$3.45Melamine laminated door skin panels are a type of manufactured hot press molded HDF panels, used high grade HDF panel with thin sheets of substrates (water proof) melamine paper, using for making doors.

7 Commentaire(s) -

Raw MDF Raw MDF

$23.00Medium-density fiberboard (MDF) is an engineered wood panel made by breaking down hardwood or softwood residuals into wood fibers, MDF does not contain knots or rings, making it more uniform than natural woods during cutting and working.

1 Commentaire(s) -

Veneer Door Skin Veneer Door Skin

$4.80Veneer laminated door skin panels are a type of manufactured hot press molded HDF panels, used high grade HDF panel with thin sheets of natural veneer made from log, using for making doors.

2 Commentaire(s)

Nouveaux produits

-

Raw MDF

$23.00 -

Melamine Door Skin

$3.45 -

Construction Plywood

$12.00