00135

New product

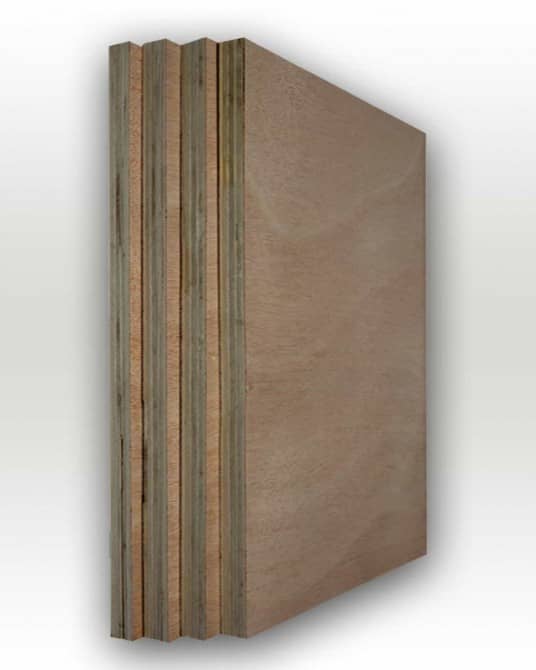

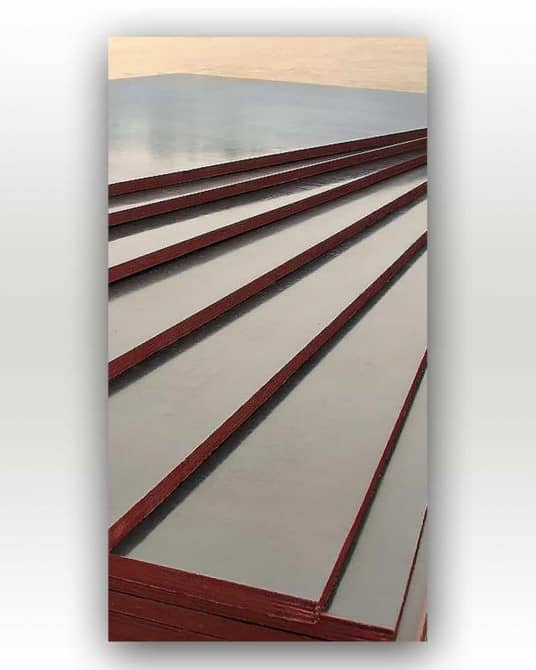

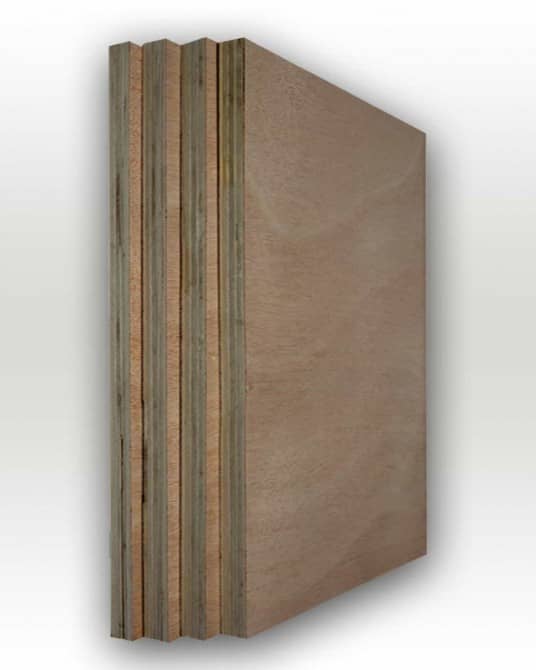

Plywood

NewEn savoir plus

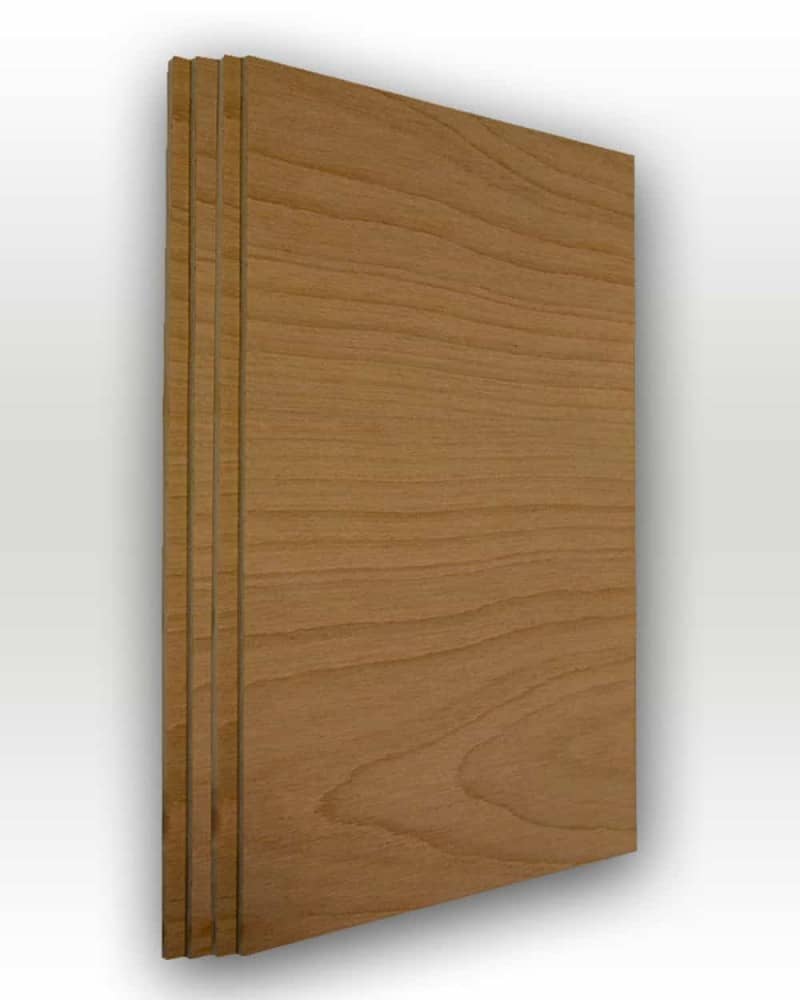

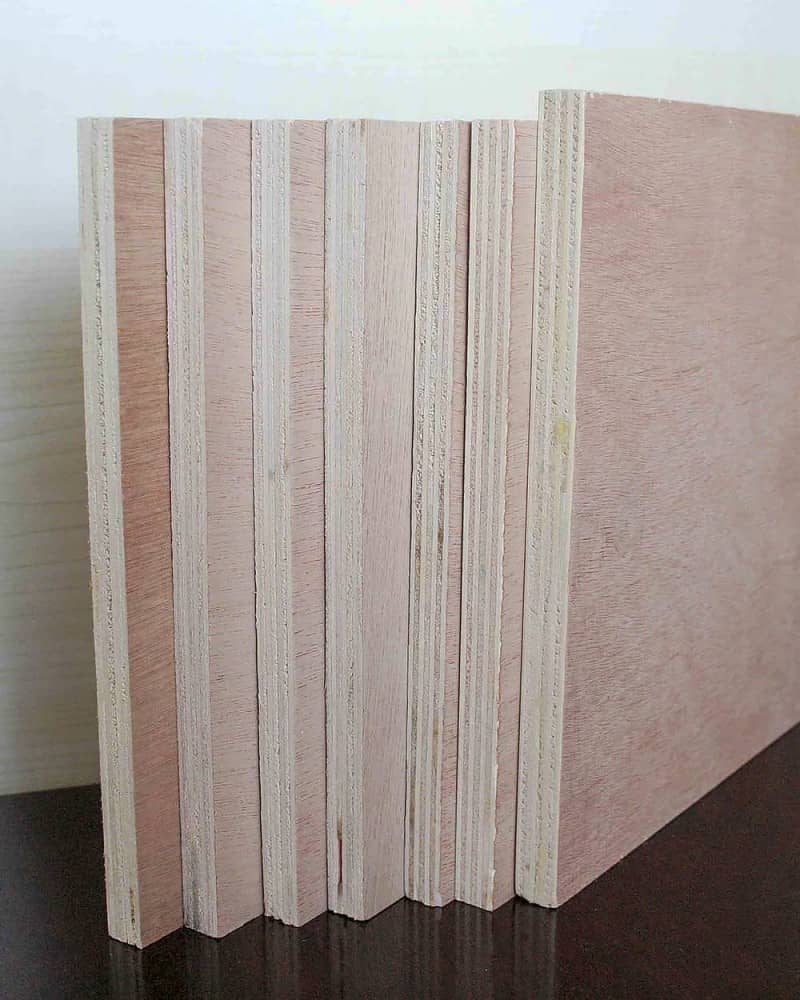

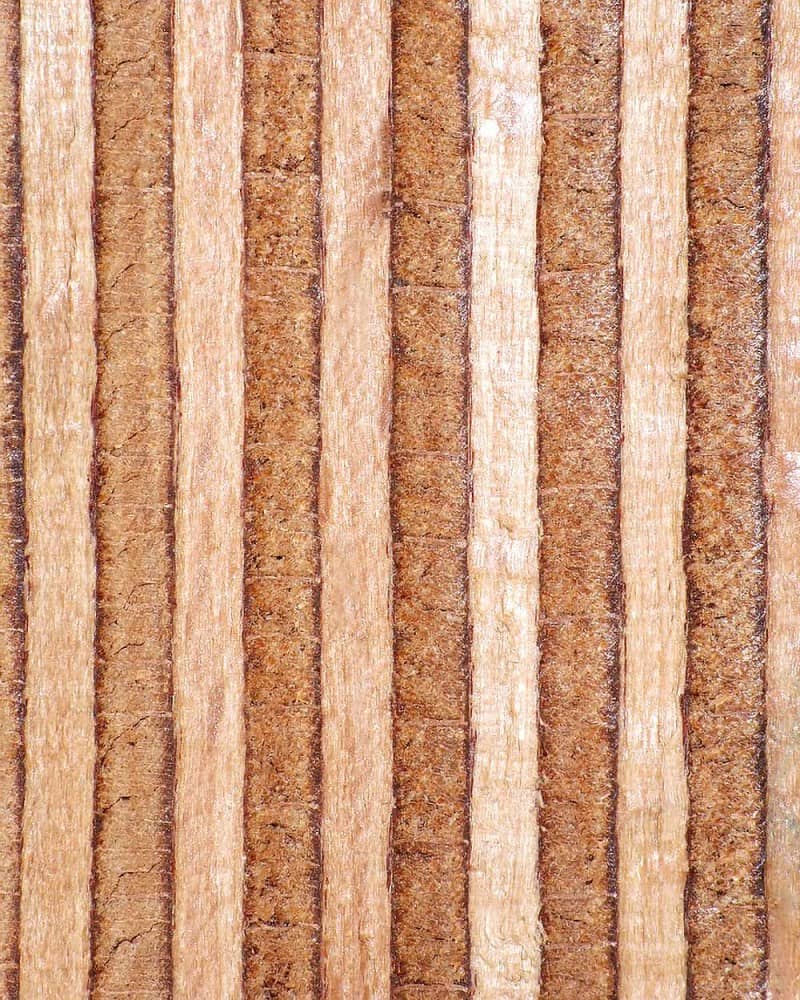

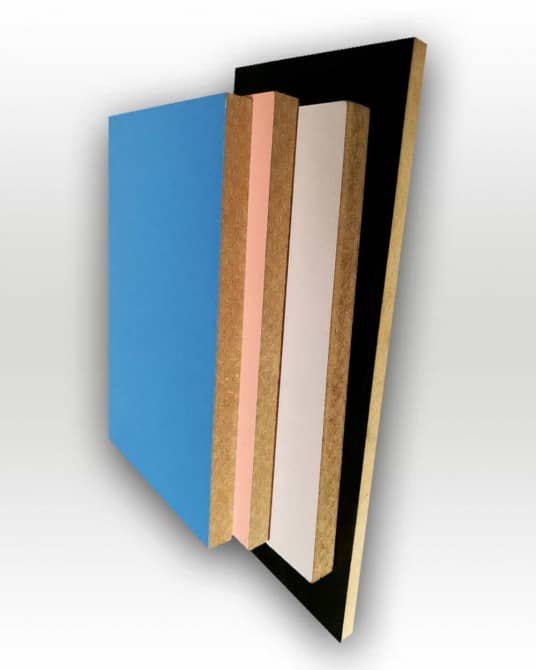

Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. All plywood’s bind resin and wood fiber sheets (cellulose cells are long, strong and thin) to form a composite material. This alternation of the grain is called cross-graining and has several important benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces expansion and shrinkage, providing improved dimensional stability; and it makes the strength of the panel consistent across all directions.

There is usually an odd number of plies, so that the sheet is balanced, this reduces warping. Because plywood is bonded with grains running against one another and with an odd number of composite parts, it has high stiffness perpendicular to the grain direction of the surface ply. Smaller, thinner, and lower quality plywood’s may only have their plies (layers) arranged at right angles to each other. Some better-quality plywood products will by design have five plies in steps of 45 degrees (0, 45, 90, 135, and 180 degrees), giving strength in multiple axes.

A typical plywood panel has face veneers of a higher grade than the core veneers. The principal function of the core layers is to increase the separation between the outer layers where the bending stresses are highest, thus increasing the panel's resistance to bending. Within Europe basic plywood can be divided into three main categories: birch plywood (density approx. 680 kg/m3), mixed plywood (density approx. 620 kg/m3) and conifer plywood’s (density 460-520 kg/m3). Plywood are thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another.

Avis

Avis

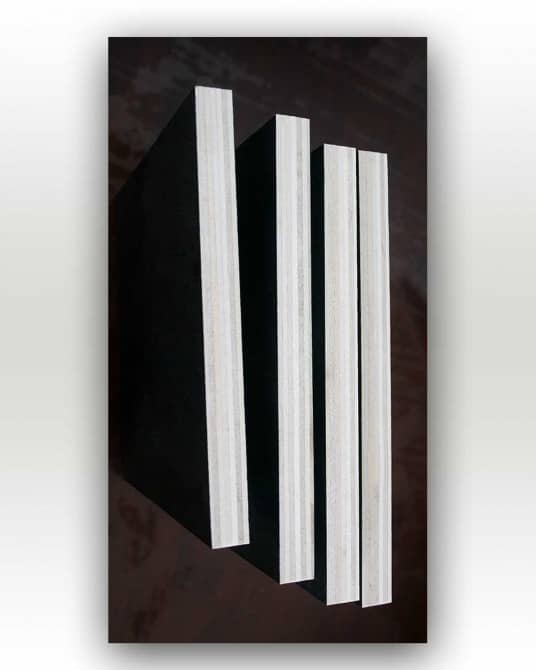

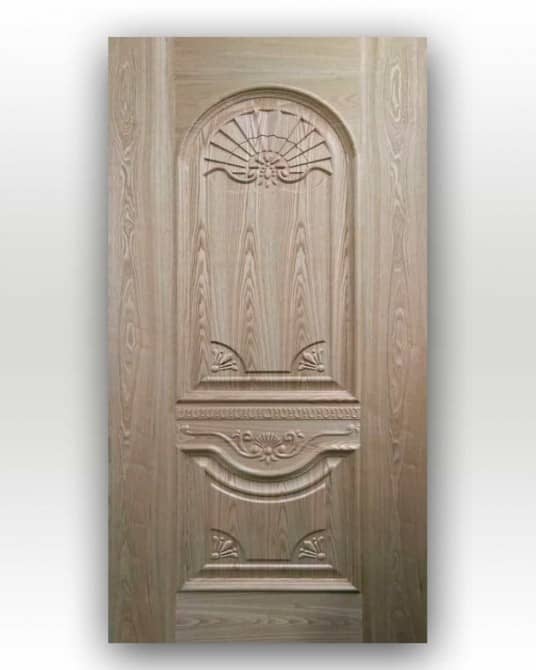

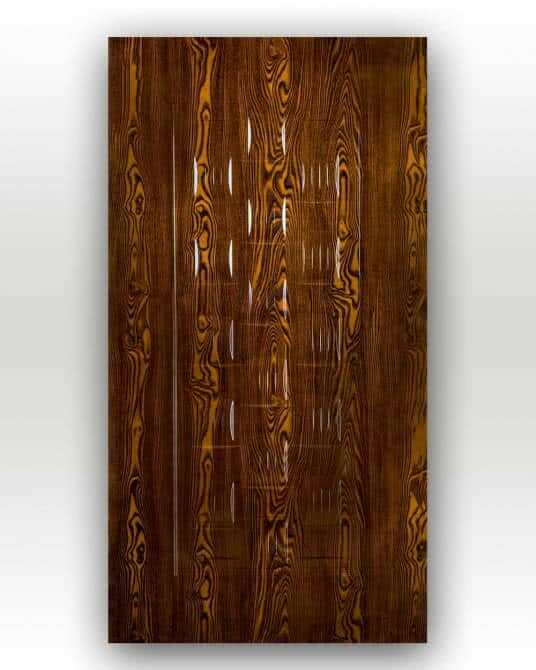

Graphique des motifs

Graphique des motifs

| PATTERN CODE | PATTERN | ||||||||

|---|---|---|---|---|---|---|---|---|---|

|

BWM 01 |

BWM 02 |

BWM 03 |

BWM 04 |

BWM 05 |

|

|

|

|

|

|

BWM 05A |

BWM 06 |

BWM 07 |

BWM 08 |

BWM 09 |

|

|

|

|

|

|

BWM 10 |

BWM 11 |

BWM 12 |

BWM 13 |

BWM 14 |

|

|

|

|

|

|

BWM 15 |

BWM 16 |

BWM 17 |

BWM 18 |

BWM 19 |

|

|

|

|

|

|

BWM 20 |

BWM 21 |

BWM 22 |

BWM 23 |

BWM 24 |

|

|

|

|

|

|

BWM 102 |

BWM 106 |

BWM 118 |

BWM 119 |

BWM 120 |

|

|

|

|

|

|

ASH 101 |

BEE 101 |

BWN 101 |

CHE 101 |

MAH 101 |

|

|

|

|

|

|

OAK 101 |

RWD 101 |

RWN 101 |

SAP 101 |

TEA 101 |

|

|

|

|

|

livraison

livraison

|

No matter where you live, your order will be shipped in time and delivered right to your port. The packages are handled with utmost care, so the ordered products will be handed to you safe and sound, just like you expect them to be. |

|

Quality.

Easy bending to make nice shapes.